| 1 편 주 조 |

|---|

|

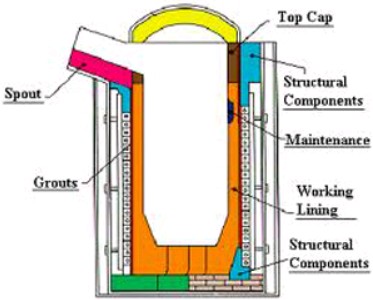

도가니로(crucible furnace)

1.전기 도가니로(electric crucible furnace)

Electric crucible furnaces are similar to gas fired-crucible furnaces, but utilize electric

resistance-heating elements to heat the crucible and melt the aluminum. Like their gas counterpart,

electric crucible furnaces are small and are typically used when alloy flexibility is the most important.

|

|||

|

|||

|

The efficiency of a furnace is the ratio of heat input to useful output. To calculate the furnace efficiency you divide the theoretical amount of heat needed by the actual amount of heat used to melt a specific amount of metal. |

|||

lift-out crucible furnace |

tilting crucible furnace |

stationary crucible furnace |

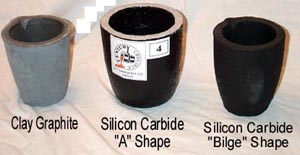

도가니 |

| 2. gas 도가니로(gas-fired crucible furnace) | |||

|

gas-fired crucible furnace |

||

| 3.coke 도가니로 (coke-fired crucible furnace) | |||

coke-fired crucible furnace |

|||