|

Bessemer식 전로(Bessemer式 轉爐; Bessemer converter)

Bessemer process was the first inexpensive industrial process for the mass-production of steel from

molten pig iron. The process is named after its inventor, Henry Bessemer, who took out a patent on

the process in 1855. The process was independently discovered in 1851 by William Kelly.

The process had also been used outside of Europe for hundreds of years, but not on an industrial scale.

The key principle is removal of impurities from the iron by oxidation through air being blown through

the molten iron. The oxidation also raises the temperature of the iron mass and keeps it molten.

|

The details of the process

- Bessemer Converter

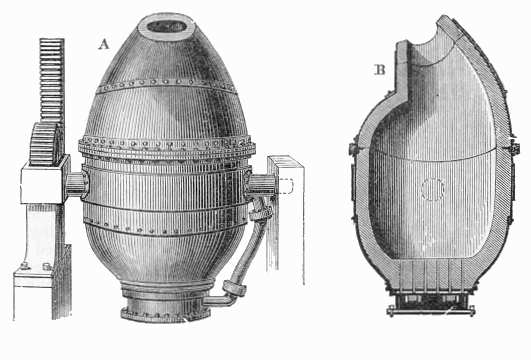

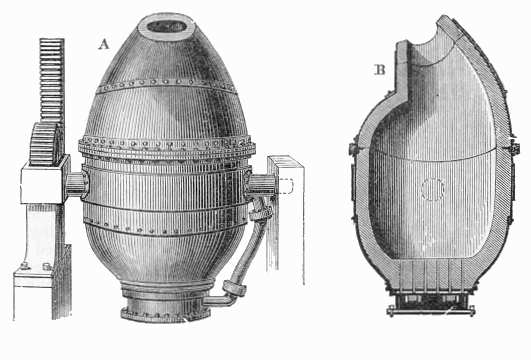

The process is carried on in a large ovoid steel container lined with clay or dolomite called

the Bessemer converter. The capacity of a converter was from 8 to 30 tons of molten iron with

a usual charge being around 15 tons. At the top of the converter is an opening, usually tilted

to the side relative to the body of the vessel, through which the iron is introduced and the

finished product removed. The bottom is perforated with a number of channels called tuyeres

through which air is forced into the converter. The converter is pivoted on trunnions so that

it can be rotated to receive the charge, turned upright during conversion, and then rotated again

for pouring out the molten steel at the end.

- Oxidation

The oxidation process removes impurities such as silicon, manganese, and carbon as oxides.

These oxides either escape as gas or form a solid slag. The refractory lining of the converter

also plays a role in the conversion - the clay lining is used in the acid Bessemer, in which

there is low phosphorus in the raw material. Dolomite is used when the phosphorus content

is high in the basic Bessemer (limestone or magnesite linings are also sometimes used instead

of dolomite) - this is also known as a Gilchrist-Thomas converter. In order to give the steel

the desired properties, other substances could be added to the molten steel when conversion

was complete, such as spiegeleisen (an iron-carbon-manganese alloy).

- Managing the process

When the required steel had been formed, it was poured out into ladles and then transferred into

moulds and the lighter slag is left behind. The conversion process (called the "blow") was

completed in around twenty minutes. During this period the progress of the oxidation of the

impurities was judged by the appearance of the flame issuing from the mouth of the converter:

the modern use of photoelectric methods of recording the characteristics of the flame has greatly

aided the blower in controlling the final quality of the product. After the blow, the liquid metal

was recarburized to the desired point and other alloying materials are added, depending on the desired

product.

|