| 4 편 절 삭 가 공 |

|---|

|

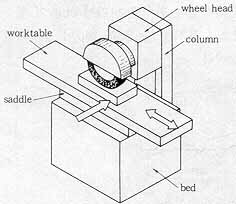

Surface Grinding Machine

|

|

horizontal spindle surface grinding machine with reciprocating table |

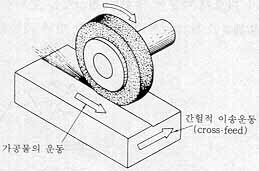

수평축 평면연삭기의 운동 |

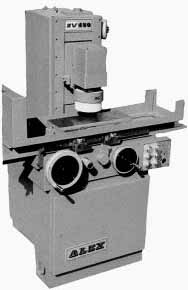

CNC horizontal spindle surface grinding machine with reciprocating table |

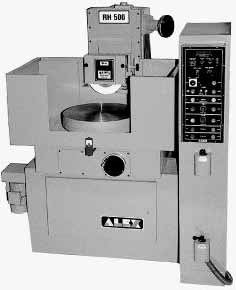

horizontal spindle surface grinding machine with rotary table |

vertical spindle surface grinding machine with reciprocating table |

vertical spindle surface grinding machine with rotary table |

| Better Way Grinding Inc. offers opposed double disc surface grinding for parts of most makes, shapes, and sizes. We are capable of grinding parts that range from .010 of an inch to 4 inches in thickness, and up to 5 inches in width by 12 feet in length. Our feed-thru machines are equipped with various automated systems which have the capability of grinding 10,000 or more pieces per hour. We also do spot type grinding, so we welcome 1 to 1,000,000 parts or more. No matter what the quantity of parts that our customers need ground, we offer the best value, with regards to price and quality. | |

|

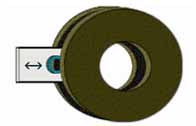

METHOD 1: Feed-Thru Disc Grinding

In the Feed-Thru method, parts are fed between the opposed disc abrasives using upper and lower rails as supports and guides. This method provides the highest rate of production and is the most cost-effective for our clients since it is capable of processing large production runs in a relatively short period of time, roughly 10,000 or more pieces per hour. |

|

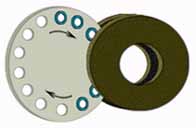

METHOD 2: Rotary Disc Grinding

In the Rotary method, parts are fed between the opposed disc abrasives while nested and contained in a rotating carrier wheel. It is normally used to grind odd-shaped or odd-configured parts. This method provides the second highest rate of production and gives us the capability to grind just about any shape part that our customers require. |

|

METHOD 3: Reciprocating (Spot Type) Disc Grinding

In the Reciprocating method, parts are reciprocated between the opposed disc abrasives while nested and contained in a specially designed carrier. This method is designed for oversized or extremely odd-configured parts that need to be ground one at a time. This method provides the third highest production rate and gives us the capability to grind just about any size part that our customers require. |