A deep hole is defined by its depth to diameter ratio (D:d), typically greater than 10:1. Gundrilling is a precision process to drill deep holes in a variety of materials, from aluminum to superalloys. Good finish, tight diameter control and straight-ness are part of the finished process with deep hole drilling methods.

Deep hole drilling is beneficial across several applications. Oil and gas exploration equipment, armaments, aerospace equipment, and engines are common applications for deep hole drilling and machining processes. In each of these industries, hole qualities are necessary for high-performance end products, such as landing gear that easily retracts. Production requires deep hole drilling that is reliable, accurate, and time-efficient.

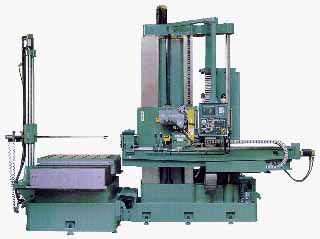

Advances in technology allow common CNC machining centers, equipped with high pressure through-spindle coolant, to be capable of gundrilling up to a certain depth-to-diameter ratio.

UNISIG produces the most capable deep hole drilling machines on the market, with applications exceeding 400:1 depth to diameter ratio.

Drilling Process

- Typically used for non-symmetrical components or round parts requiring holes offcenter

- Cutting speed is determined by tool spindle speed

- Drill drift can be significant compared to rotating workpiece or counter-rotating process

Rotating Workpiece

- Used for round parts with a deep hole on-center

- Cutting speed is determined by part, balanced to allow high rotating speeds

- Drill drift is reduced compared to rotating tool only

Counter-rotating Tool and Workpiece

- Used for round parts with a deep hole on-center

- Cutting speed determined by combination of tool and workpiece rotation

- Provides best hole straightness and concentricity compared to rotating workpiece or rotating tool

Deep Hole Drilling Tools

Gundrill Tooling

- Small diameter drilling, typically 1 - 50mm [0.04 -2.00in] diameter holes

- High-pressure coolant is introduced through the spindle and gundrill center

- Chips are discharged on the outside of the tool

- Special forms can be ground in tool tip

BTA tooling

- Larger diameter drilling, typically 20 - 200mm [0.79 - 8 inch]

- Counter-boring and trepanning tools cover larger range, up to 500mm [20 inch] diameter

- High-pressure coolant is introduced around the outside of the tool

- Chips are discharged through the tool center and machine spindle

- High penetration rates and power requirements compared to gundrill tooling

Deep Hole Machining

After drilling, additional machining methods can further improve deep hole concentricity, straightness, surface finish, and more. These methods machine the inside surface of the hole, much like other external machining processes, and most can be performed on a BTA deep hole drilling machine.

Processes are performed on a workpiece with an existing bore due to prior drilling or centrifugal casting, and an inside diameter surface exists. Many of these deep hole machining processes have been optimized for specific applications, such as skiving machines for the hydraulic cylinder industry, or bottle boring for landing gear actuators.

|

gun drill

gun drill