|

(1)

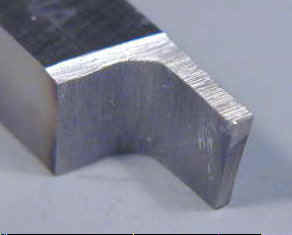

A parting tool is deeper and narrower than a turning tool. It is designed for making narrow grooves and for

cutting off parts. When a parting tool is installed, ensure that it hangs over the tool holder enough that

the the holder will clear the workpiece (but no more than that). Ensure that the parting tool is perpendicular to

the axis of rotation and that the tip is the same height as the center of the part. A good way to do this is to

hold the tool against the face of the part. Set the height of the tool, lay it flat against the face of the part,

then lock the tool in place. When the cut is deep, the side of the part can rub

against sides of the groove, so it's especially important to apply cutting fluid. In this clip, a part is cut

off from a piece of stock.

(2)

Cutting-Off Machines are single-spindle, lathe-type machines designed for production cutoff of round tubing,

pipe and solid bar stock. Stock is fed through the spindle to a stop which gages the cut length, then held by

a collet and rotated while being cut off with tools mounted on cross slides. Parts have square cut ends with

minimum burr. Multiple cross slides permit deburring or chamfering the O.D. of both ends while cutting off.

Any type of material that can be turned with standard tooling can be cut off.

|