| 6 편 측 정 |

|---|

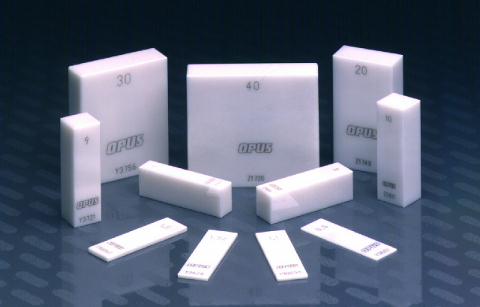

Gage Block

ceramic gage block

|

|

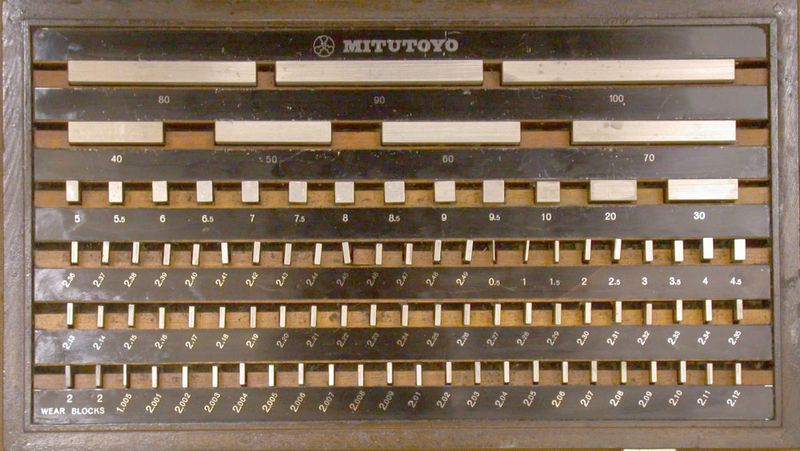

tungsten carbide gage block

|

|

|

Gauge blocks (also known as gauge blocks, Johansson gauges, slip gauges, Jo blocks, block gauges) are

precision ground and lapped measuring standards.

Rectangular, square, wear, scribing and angle gage blocks are available in hardened steel, carbide

and ceramic materials. They are used as references for the setting of measuring equipment such as micrometers, sine bars, dial indicators (when used in an inspection role). They are available in various grades depending on their intended use.

|

|