|

Sine Bar & Sine Plate

|

|

|

- To set an angle on any sine device, whether it is a sine bar, sine plate, compound sine plate,

or other sine tool, you must first determine the center distance of the device (C) and the angle

you wish to set (A).

- Next, you must look up the 'setting constant' in the appropriate table.

The sine tables provided in this booklet are the basic sizes needed to set an angle on most sine products.

For center distances other than those sizes listed, use the appropriate multiple of the constant

determined from the basic chart.

- After determining the appropriate constant, assemble a stack of gage blocks (G) equal in size to

that constant.

- Place these gage blocks under the gage block roll of the sine device, and the desired angle is set.

- Tighten the locking mechanism on those devices that have one, and you're ready to go.

|

|

|

A sine bar is a tool used to measure angles in metalworking.

It consists of a hardened, precision ground body with two precision ground cylinders fixed at the ends.

The distance between the centers of the cylinders is precisely controlled, and the top of the bar is

parallel to a line through the centers of the two rollers. The dimension between the two rollers is

chosen to be a whole number(for ease of later calculations) and forms the hypotenuse of a triangle

when in use. The image shows a 10 inch and a 100 mm sine bar.

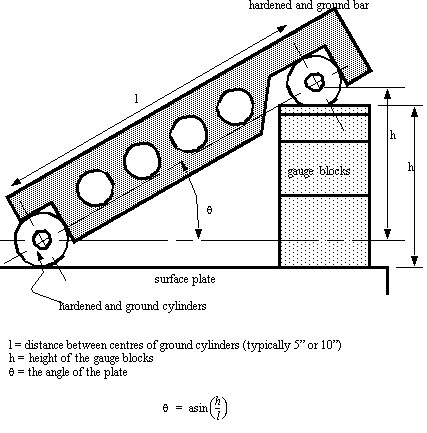

When a sine bar is placed on a level surface the top edge will be parallel to that surface.

If one roller is raised by a known distance, usually using gauge blocks, then the top edge of the bar

will be tilted by the same amount forming an angle that may be calculated by the application of the

sine rule.

- The hypotenuse is a constant dimension(100 mm or 10 inches in the examples shown).

- The height is obtained from the dimension between the bottom of one roller and the table's surface.

- The angle is calculated by using the sine rule.

|

sine plate

sine plate

☜

|

sine plate는 측정기가 아니고 공작물의 고정구이나 각의 조정이 sine bar에서와

같기 때문에 여기에 소개한다.

- Hardened steel top plate has tapped holes for use with clamping devices.

- The roll bar is made from hardened steel, ground and lapped for straightness and roundness.

- Swivel block provides full face contact with gage blocks keeping them securely in place.

- Exclusive locking device inside the hinge roll provides a positive lock with an expanding action. Both screws lock toward the front of the unit, pulling the top plate down on the set-up gage blocks without distortion. Hinge is made from hardened steel, ground and lapped.

- Angular accuracy of set-ups is guaranteed to be within 5 seconds of arc up to 15 deg., 10 seconds up to 30 deg. and 15 seconds up to 45 deg.

- Side and back rail included.

|