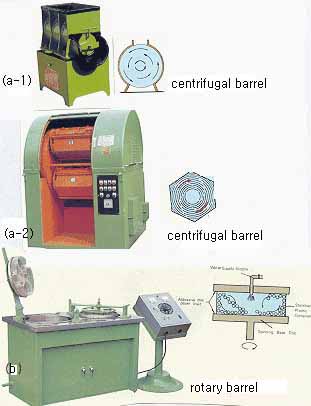

(a) centrifugal barrel finishing machine:

Centrifugal barrel equipment consists of a turret that rotates at high speeds.

Mounted to the turret are two to four closed barrels containing the finishing mass.

These barrels rotate at slower speeds than the turret and in the opposite direction.

This complex motion creates high centrifugal forces and smooth media sliding action

within the barrels. Process times are 20 to 40 times faster than for vibratory machines.

Smaller media is used in this high-energy process, providing better access to all

part surfaces for development of extremely fine finishes. The force applied by

the media can be varied so that two operations can be combined into a single

cycle - deburring and surface refining for example. Vessel capacities for this type

of equipment range from 1.0 - 10 ft³.

Another high-energy process uses the centrifugal disk equipment.

Newer than the other finishing machines, this design uses a rotating disk

in the bottom of a cylindrical vessel that forces the mass out and up against

the stationary vessel wall, where it slows down. The mass continues to slow down as

it reaches the top of the vessel and then falls down the center toward the rotating

disk to repeat the cycle. So, the media and parts move at varying speeds which

generates desired surface finishes in cycle times between those of vibratory machines

and centrifugal barrels. Parts can be inspected easily during the process because

the vessel has an open top and the process is easily automated. The load can be

emptied through an opening in the side of the container or the whole vessel can

be tilted to dump the load. Media separation, washing, classification, and return

can be accomplished using methods similar to those used with tub vibratory machines.

Some units can perform with dry or wet media. Equipment capacities range from 0.5ft³ to 20ft³.

Centrifugal barrel machines are high energy machines, designed to rapidly process

your parts, they are capable of producing a high polish finish on aluminum and

stainless steel with the proper process.

(b) rotary barrel finishing machine:

The "elder statesman" of mass finishing equipment, the rotary barrel, still performs

with excellence in many applications. However, it is slow, since it applies the

lowest energy of all mass-finishing equipment. It is messy and therefore often confined

to the dim, dark recesses of the plant. It requires an operator with much more skill

and training than those who operate vibrators, and it is not normally recommended

today except in unusual cases.

The newest mass-finishing machine has a round chamber with a rotating disc in the bottom.

The disc rotates and forces the mass out and up against the stationary chamber wall,

where it begins to slow down. The mass slows further as it reaches the top of the load,

just before it descends back down the middle toward the spinning disc, where the cycle is repeated.

The constantly varying speeds of media and parts generate excellent surface finishes

in cycles intermediate between the vibratory machines and the centrifugal barrel.

(c) vibratory barrel finishing machine:

Driven by horizontal motor and by means of special deriving working tub along

with the base spring to produce high frequency vibration to achieve requested

efficiency processing.

Due to the advantages of large inlet and extensive usefulness,

it is the best machine for large and longer workpiece.

In vibratory finishing, energy in the form of vibratory forces is transformed

by the machine's drive system into a mass of loose media and then into the parts.

The entire load is in motion at the same time so that the media act against

the parts throughout the complete mass.

Elements. Basic elements of the system include the machine, the media, and the

compound and/or water solution. Selection of each depends primarily on the parts

being run - that is, the type of parts: size, shape, and condition; and the work

to be accomplished.

Primary functions of the media are to keep the parts separated during processing,

to provide a cutting action for removing burrs or smoothing surfaces, and/or to

brighten or clean the workpiece surfaces. The ratio of media to parts, by volume,

determines the degree of parts separation; at high ratios, parts are well separated

and have little contact. This is an important consideration when part finish is critical.

Role of compounds. Liquid compounds are used to keep parts and media clean,

inhibit corrosion, lubricate, cut, cushion parts against damage, suspend tiny

loose abrasive particles, and for such other specialized functions as foam control

and to speed up drying. In many cases, the type of compound used and its degree of

dilution with water determines the success or failure of the entire system.

|