| 5 편 수 기 가 공 및 조 립 |

|---|

|

Pullers

|

|

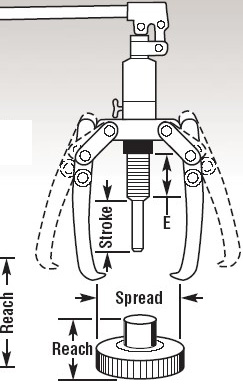

(1) Mechanical Pullers

In order to perform a proper pull, be certain that you firmly grip the gear, bearing, wheel, pulley,

etc. and apply force to the shaft. Use a 3-jaw puller instead of a 2-jaw whenever possible for better

gripping power and a more uniform displacement of pulling force. |

|

|

|

|

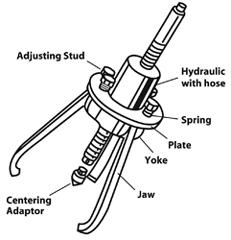

(1) hydraulic Pullers

Hydraulic pullers provide an efficient means for the removal of gears, bearings, wheels, pulleys and

other press fit parts. Hydraulic power provides a controlled means of applying force without the need

for hammering, heating or prying.

|

|

|

separating hydraulic type |