|

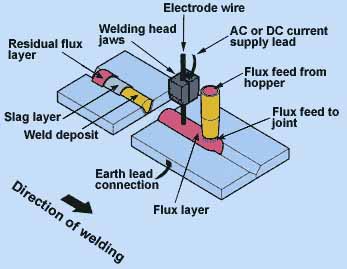

The submerged-arc welding(SAW) process is similar to MIG where the arc is formed between a continuously-fed

wire electrode and the workpiece, and the weld is formed by the arc melting the workpiece and the wire. However,

in SAW a shielding gas is not required as the layer of flux generates the gases and slag to protect the weld pool

and hot weld metal from contamination. Flux plays an additional role in adding alloying elements to the weld

pool.

Essential equipment

Essential equipment components for SAW are:

- power source

- wire gun

- flux handling

- protective equipment

As SAW is a high current welding process, the equipment is designed to produce high deposition rates.

Power source

SAW can be operated using either a DC or an AC power source. DC is supplied by a transformer-rectifier and AC is

supplied by a transformer. Current for a single wire ranges from as low as 200A (1.6mm diameter wire) to as

high as 1000A (6.0mm diameter wire). In practice, most welding is carried out on thick plate where a single

wire (4.0mm diameter) is normally used over a more limited range of 600 to 900A, with a twin wire system

operating between 800 and 1200A.

In DC operation, the electrode is normally connected to the positive terminal. Electrode negative (DCEN) polarity

can be used to increase deposition rate but depth of penetration is reduced by between 20 and 25%. For this

reason, DCEN is used for surfacing applications where parent metal dilution is important. The DC power source

has a 'constant voltage' output characteristic which produces a self-regulating arc. For a given diameter of

wire, welding current is controlled by wire feed speed and arc length is determined by voltage setting.

AC power sources usually have a constant-current output characteristic and are therefore not self-regulating.

The arc with this type of power source is controlled by sensing the arc voltage and using the signal to control

wire feed speed. In practice, for a given welding current level, arc length is determined by wire burnoff

rate, i.e. the balance between the welding current setting and wire feed speed which is under feedback

control.

Welding gun

SAW can be carried out using both manual and mechanised techniques. Mechanised welding, which can exploit

the potential for extremely high deposition rates, accounts for the majority of applications.

-

Manual welding

For manual welding, the welding gun is similar to a MIG gun, with the flux which is fed concentrically around the

electrode, replacing the shielding gas. Flux is fed by air pressure through the handle of the gun or from

a small hopper mounted on the gun. The equipment is relatively portable and, as the operator guides the gun

along the joint, little manipulative skill is required. However, because the operator has limited control over

the welding operation (apart from adjusting travel speed to maintain the bead profile) it is best used for

short runs and simple filling operations.

Mechanised welding - single wire

As SAW is often used for welding large components, the gun, wire feeder and flux delivery feed can be mounted

on a rail, tractor or boom manipulator. Single wire welding is mostly practised using DCEP even though AC will

produce a higher deposition rate for the same welding current. AC is used to overcome problems with arc blow,

caused by residual magnetism in the workpiece, jigging or welding machine.

Wire stickout, or electrode extension - the distance the wire protrudes from the end of the contact tip - is

an important control parameter in SAW. As the current flowing between the contact tip and the arc will preheat

the wire, wire burnoff rate will increase with increase in wire stickout. For example, the deposition rate

for a 4mm diameter wire at a welding current of 700A can be increased from approximately 9 kg/hr at the

normal 32mm stickout, to 14 kg/hr at a stickout length of 178mm. In practice, because of the reduction in

penetration and greater risk of arc wander, a long stickout is normally only used in cladding and surfacing

applications where there is greater emphasis on deposition rate and control of penetration, rather than

accurate positioning of the wire.

Mechanised welding - twin wire

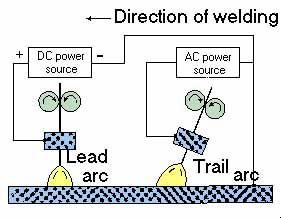

Tandem arc connections

SAW can be operated with more than one wire. Although up to five wires are used for high deposition rates, e.g.

in pipe mills, the most common multi-wire systems have two wires in a tandem arrangement. The leading wire is

run on DCEP to produce deep penetration. The trailing wire is operated on AC which spreads the weld pool, which

is ideal for filling the joint. AC also minimises: interaction between the arcs, and the risk of lack of fusion

defects and porosity through the deflection of the arcs (arc blow). The wires are normally spaced 20mm apart

so that the second wire feeds into the rear of the weld pool.

Gun angle

In manual welding, the gun is operated with a trailing angle, i.e. with the gun at an angle of 45

degrees (backwards) from the vertical. In single wire mechanised welding operations, the gun is perpendicular

to the workpiece. However, in twin wire operations the leading gun is normal to the workpiece, with the

trailing gun angled slightly forwards between an angle of 60 and 80 degrees. This reduces disturbance of

the weld pool and produces a smooth weld bead profile.

Flux handling

Flux should be stored in unopened packages under dry conditions. Open packages should be stored in a

humidity-controlled store. While flux from a newly-opened package is ready for immediate use, flux which

has been opened and held in a store should first be dried according to manufacturer's instructions. In

small welding systems, flux is usually held in a small hopper above the welding gun. It is fed

automatically (by gravity or mechanised feed) ahead of the arc. In larger installations the flux is stored

in large hoppers and is fed with compressed air. Unused flux is collected using a vacuum hose and returned to

the hopper.

Note:

Care must be taken in recycling unused flux, particularly regarding the removal of slag and metal dust

particles. The presence of slag will change the composition of the flux which, together with the wire,

determines the composition of the weld metal. The presence of fine particles can cause blockages in the

feeding system.

Protective equipment

Unlike other arc welding processes, SAW is a clean process which produces minimum fume and spatter when welding

steels. (Some noxious emissions can be produced when welding special materials.) For normal applications,

general workshop extraction should be adequate.

Protective equipment such as a head shield and a leather apron are not necessary. Normal protective

equipment (goggles, heavy gloves and protective shoes) are required for ancillary operations such as slag removal

by chipping or grinding. Special precautions should be taken when handling flux - a dust respirator and gloves

are needed when loading the storage hoppers.

|