|

Because of the close relationship between the outside diameter of the thread and the workpiece blank, it is critical

that blank diameters be highly accurate. The material flow rate is calculated based on the specified blank diameter

and variation. Either over or under this diameter will produce unacceptable threads.

Undersized material will not fully flow into the roller dies and will cause undersized threads. Oversized blanks

will exert undue pressure on the rollers and head resulting in potential damage to the thread rolling unit.

Thread rolling success is determined in large part by the shape of the form to be produced. Most of the threads

produced are made to the 60 degree Unified and similar standards, which are easily rolled. Most of the rollers used

to produce these forms have relatively sharp crests, usually with radius edge to help the die penetrate the material.

The angles of these threads, 30 degrees on each flank, provide the force to make the material flow axially and

radially in a controlled and predictable manner.

Acme and worm threads can be rolled, but the relatively large amount of material displacement and the distance

the material must move can cause flaking on the flanks. Rollability of these types of threads is improved by

changing the thread’s root configuration from flat bottom to a radius. Thread rolling can also be applied to

burnishing, knurling and, in some cases, swaging operations.

|

|

Axial Thread Rolling

Depending on the type of machine and thread that needs to be manufactured, shops have several thread rolling

configurations from which to choose. An axial thread roller moves from the tailstock end of the turning center,

along the workpiece blank centerline, to create a thread. General working ranges for axial heads are from 0.06 to

9 inches in diameter.

Thread rolling can be applied to create a variety of forms in workpiece blanks.

The axial head is usually mounted in one of the turning center’s turret tool pockets. In one pass, three

(or up to six) rollers are fed onto the blank and activated by the rotation of the workpiece blank.

The arrangement of the rollers on an axial head allows the blank to pass through, which enables threads that are

longer than the roller width to be formed. The first few threads on these heads are progressive, like a tap or

broach, and require a chamfer on the workpiece blank. Shorter progressions can be used for work up to shoulders

or other workpiece features, but roller life can be affected by the additional stress.

|

|

Tangential Thread Rolling

As the name implies, the tangential roller head makes its threads by approaching the workpiece blank from the side.

Sometimes called side rolling or cross slide heads, tangential thread roller are designed to roll threads by pushing,

at a controlled feed rate, two fixed parallel rolls onto the rotating component. Mechanical or servo feed is

required for tangential thread rolling. It is not possible to operate these rollers manually.

The rolls make square, tangential contact with the workpiece blank diameter forcing the material to plastically flow

uniformly, taking the shape of the roller dies. This forming process is very fast and produces a precision profile,

which is burr free.

In operation, the tangential roller will produce a complete thread in 15 to 30 revolutions of the workpiece blank.

An advantage of this thread roller type is it can form threads very close (within one thread or sometimes less) to

either the front or back of a shoulder or other workpiece feature.

Tangential rollers only roll threads within the width of the rollers. Working width ranges for Fette’s tangential

rolls are from 0.61 to 1.59 inches. These rollers are not recommended for Acme and trapezoid threads because force

required is beyond the design limits of the holders.

|

|

Radial Thread Rolling

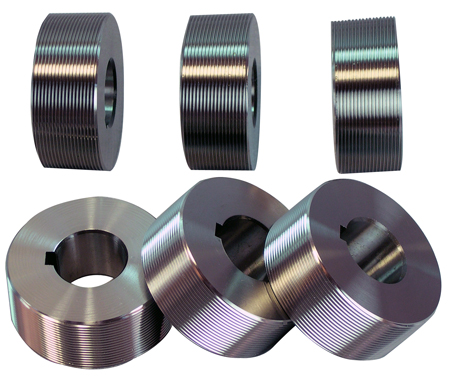

A third type of thread roller is the radial head. It uses two or three rolls to form a thread in a single rotation

of the workpiece blank.

The rolls on this type of thread roller are ground eccentrically. Starting with a flat on each roll, the thread form

is progressive. A shallow thread form starts at one side of the flat and full form at the other side.

A three roll radial head at rest uses the aligned flats to create a clearance opening. This allows the workpiece

blank to be positioned between the rolls and the finished threaded part to exit without damage to the threads.

The two roll head uses the same principle.

Internally, the rolls are set in motion by releasing tension springs attached to a rotating clutch. Once released,

the rotation of the workpiece or the roller unit continues the forward motion of the eccentric rolls until the

torque of the workpiece blank resets the clutch spring.

The working range for the radial thread rolling head is 1/16 to 2 ½ inches in diameter. Like the tangential head,

the thread length cannot exceed the width of the thread rollers.

|