| 2 편 용 접 |

|---|

|

특수 arc 용접(TIG 용접)

|

TIG 용접 |

|

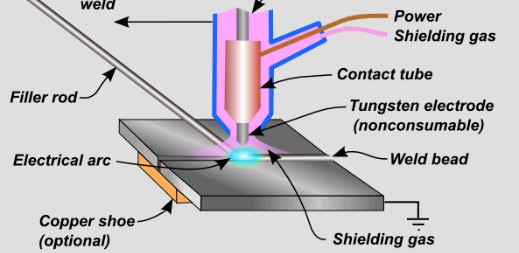

Tungsten inert gas (TIG) welding is the process of blending together reactive metals, such as magnesium and aluminum. During the welding process, an arc is formed between a pointed tungsten electrode and the area to be welded. A shielding gas is used to help create a clean weld, as it prevents oxidization from occurring. The welding method became popular and useful in the early 1940s and, as a result, has greatly propelled the use of aluminum for welding and structural processes. It is commonly used for both high quality and manual welding.

The type of gas shielding typically used for TIG welding is argon, helium, or a combination of both. When combined, these two gases can ensure a higher welding speed and welding penetration. Argon is usually preferred by most welders simply because it is heavier than air and provides better coverage when welding. Using the TIG welding process, a person can perform a variety of weld types on a number of different metals, although steel and aluminum are the most widely used. A filler rod, usually made from the same material as the base metal, is used for reinforcing joints and welding heavy metals. |