| 4 편 기 계 가 공 | |

|---|---|

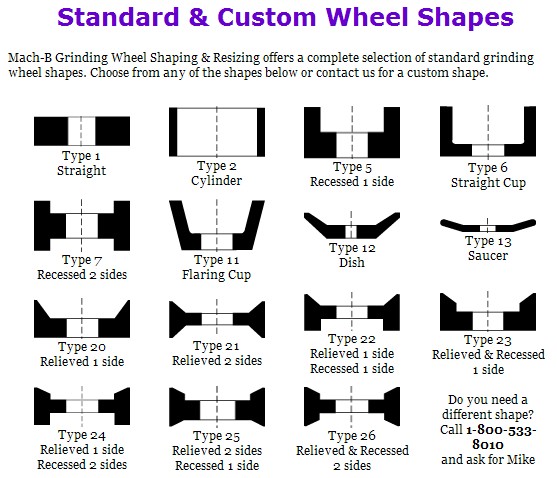

| 숫돌차의 형상 | |

|

|

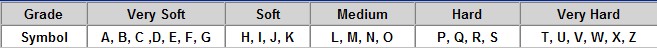

| 1. The GRADE means the relative power of the bond which holds abrasive grains in a wheel, and indicates the degree of difficulty for them to be pulled out by grinding stresses. The hardness of the work to be ground and the grinding condition determine the grade of a wheel. | ||

|

||

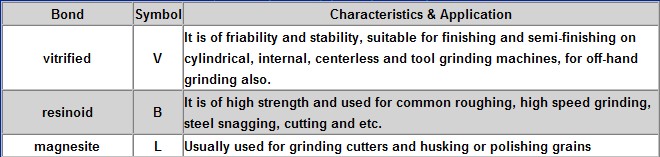

| 2. The BOND which holds the grain particles to a wheel has an important effect on the physical and chemical properties and the grinding ability of the wheel, and is to select according to the requirement on the job. We have three kind bonds of wheels, vitrified, resinoid and magnesite. | ||

|

||

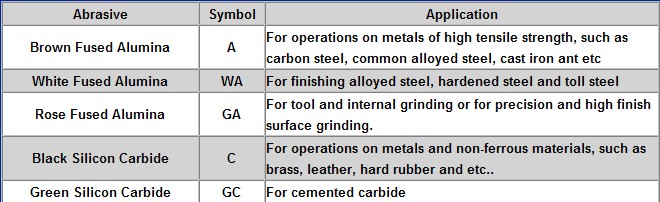

| 3. The ABRASIVES plays the major role in grinding job. There are two main kinds of conventional abrasives, Fused Alumina & Silicon Carbide, to meet the properties of materials to be ground and user's requirements. | ||

|

||

| 4. The term of "GRIT SIZE" means the size of particles and is to choose depending on user's requirement of accuracy, surface finish of the work to be ground. | ||

|

||

| 5. The grinding wheel consists of abrasive grains, bond and voids. Structure is the proportion by volume of these three elements and usually determined by the abrasive grain percentage. | ||

open |

medium |

dense |

|

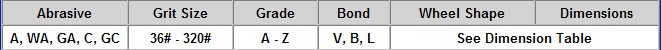

Formula of Marking a Wheel The contents of the marking system are: abrasives, grit size, grade, bond shape and dimension, all denoted by symbols in the following order. |

||

|

||

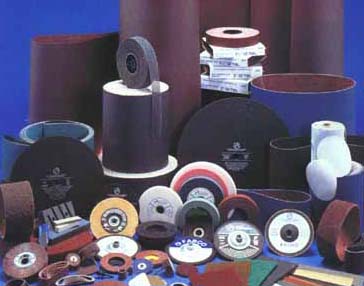

vitrified tool room wheels |

diamond & CBN wheels |

sanding, polishing & finishing |

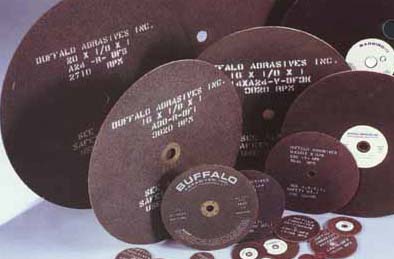

cutoff wheels |

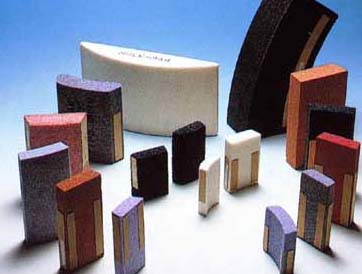

segments |

|