|

Reference 1

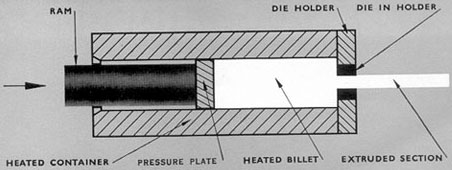

Extrusion is the process by which long straight metal parts can be produced. The cross-sections that can be produced

vary from solid round, rectangular, to L shapes, T shapes. Tubes and many other different types. Extrusion is done

by squeezing metal in a closed cavity through a tool, known as a die using either a mechanical or hydraulic press.

Extrusion produces compressive and shear forces in the stock. No tensile is produced, which makes high deformation

possible without tearing the metal. The cavity in which the raw material is contained is lined with a wear resistant

material. This can withstand the high radial loads that are created when the material is pushed the die.

Extrusions, often minimize the need for secondary machining, but are not of the same dimensional accuracy or surface

finish as machined parts. Surface finish for steel is 3 μm; (125 μ in), and Aluminum and Magnesium

is 0.8 μm (30 μ in). However, this process can produce a wide variety of cross-sections that are hard to produce

cost-effectively using other methods. Minimum thickness of steel is about 3 mm (0.120 in), whereas Aluminum and

Magnesium is about 1mm (0.040 in). Minimum cross sections are 250 mm2 (0.4 in2) for steel and less than that for

Aluminum and Magnesium. Minimum corner and fillet radii are 0.4 mm (0.015 in) for Aluminum and Magnesium, and for

steel, the minimum corner radius is 0.8mm(0.030 in) and 4 mm (0.120 in) fillet radius.

Cold Extrusion:

Cold extrusion is the process done at room temperature or slightly elevated temperatures.

This process can be used for most materials-subject to designing robust enough tooling that can withstand

the stresses created by extrusion. Examples of the metals that can be extruded are lead, tin, aluminum alloys,

copper, titanium, molybdenum, vanadium, steel. Examples of parts that are cold extruded are collapsible tubes,

aluminum cans, cylinders, gear blanks. The advantages of cold extrusion are:

- No oxidation takes place.

- Good mechanical properties due to severe cold working as long as the temperatures created are below the

re-crystallization temperature.

- Good surface finish with the use of proper lubricants.

Hot Extrusion:

Hot extrusion is done at fairly high temperatures, approximately 50 to 75 % of the melting point

of the metal. The pressures can range from 35-700 MPa (5076 - 101,525 psi). Due to the high temperatures and

pressures and its detrimental effect on the die life as well as other components, good lubrication is necessary.

Oil and graphite work at lower temperatures, whereas at higher temperatures glass powder is used.

Typical parts produced by extrusions are trim parts used in automotive and construction applications, window

frame members, railings, aircraft structural parts.

|

|

Reference 2

When pressure is applied to the ram the metal in the centre of the billet is forced through the die first and at

the end of the stroke the outer skin of the billet reaches the die. In order to preserve a homogeneous structure

of material and avoid oxide inclusions the end of the billet is not extruded, but is cut off. This portion is

termed the "discard".

Tubes. There are two processes in common use for the extrusion of tubes. The first of these is with a floating

mandrel, in which a mandrel is attached to the pressure plate and metal is extruded round this mandrel and

through a die. In this case either a hollow or a solid billet is used. With a solid billet the billet is pierced

by the mandrel as the ram is set in motion. The alternative process is the bridge mandrel technique, in which a

short mandrel is attached to the die by means of a bridge; in this process the metal is extruded over the bridge

and welds in the die assembly.

Due to difficulties of production it is not possible to produce tube with thin walls by direct extrusion, and

these must be produced as a larger extruded tube and subsequently drawn through drawing dies. Where the reduction

is considerable several drawing passes are required, with annealing of the section between passes.

|