|

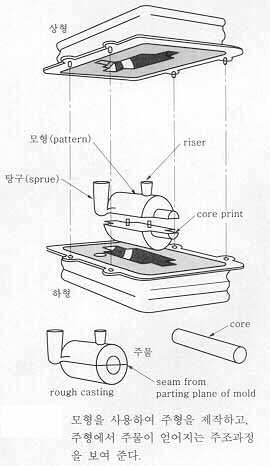

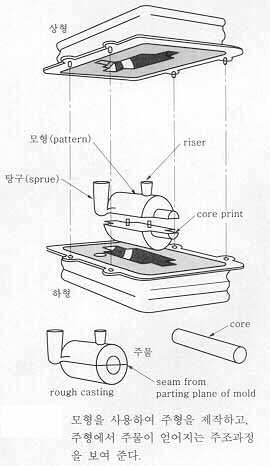

주조과정을 설명하고 다음 용어를 정의한다.

- 주형사(molding sand)

- 주형(mold)

- 상형

- 하형

- 모형(pattern)

- core

- 주형상자(flask)

- 위상자

- 아래상자

- 주물(casting)

- 주조(casting)

주형상자에 주형사로 모형을 묻어 다진다음 모형을 빼내고 그 공간에 용금을 주입하여 주물(casting)이라는 제품을 얻는 과정을 주조(casting)라 한다. 주물에 중공부를 두기 위하여 사용하는 주형을 core라 하며, 주형에 core를 밭일 자리를 내기 위하여 모형에 붙인 돌기부를 core print라 한다.

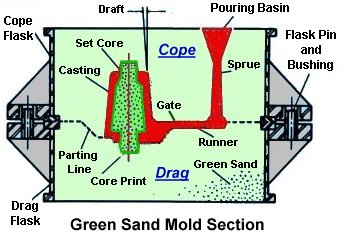

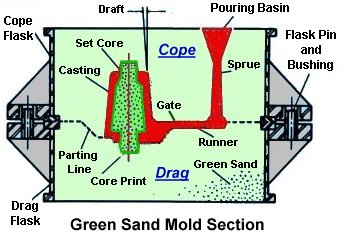

Casting is a manufacturing process where a solid is melted, heated to proper temperature (sometimes treated to modify its chemical composition), and is then poured into a cavity or mold, which contains it in the proper shape during solidification. Thus, in a single step, simple or complex shapes can be made from any metal that can be melted.

|

|

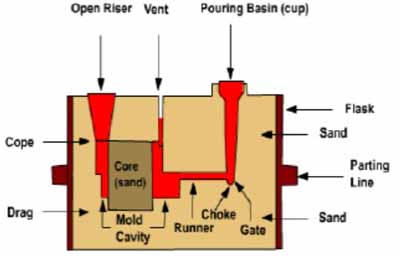

Casting Terms

- Flask: A metal or wood frame, without fixed top or bottom, in which the mold is formed. Depending upon the position of the flask in the molding structure, it isreferred to by various names such as drag - lower molding flask, cope - upper molding flask, cheek - intermediate molding flask used in three piece molding.

- Pattern: It is the replica of the final object to be made. The mold cavity is made with the help of pattern.

- Parting line: This is the dividing line between the two molding flasks that makes up the mold.

- Molding sand: Sand, which binds strongly without losing its permeability to air or gases. It is a mixture of silica sand, clay, and moisture in appropriate proportions.

- Facing sand: The small amount of carbonaceous material sprinkled on the inner surface of the mold cavity to give a better surface finish to the castings.

- Core: A separate part of the mold, made of sand and generally baked, which is used to create openings and various shaped cavities in the castings.

- Pouring basin: A small funnel shaped cavity at the top of the mold into which the molten metal is poured.

- Sprue: The passage through which the molten metal, from the pouring basin, reaches the mold cavity. In many cases it controls the flow of metal into the mold.

- Runner: The channel through which the molten metal is carried from the sprue to the gate.

- Gate: A channel through which the molten metal enters the mold cavity.

- Chaplets: Chaplets are used to support the cores inside the mold cavity to take care of its own weight and overcome the metallostatic force.

- Riser: A column of molten metal placed in the mold to feed the castings as it shrinks and solidifies. Also known as "feed head".

- Vent: Small opening in the mold to facilitate escape of air and gases.

|