| 1 편 주 조 |

|---|

|

저압주조법(低壓鑄造法; low pressure casting, pressure pouring casting, pressure casting)

|

|

|

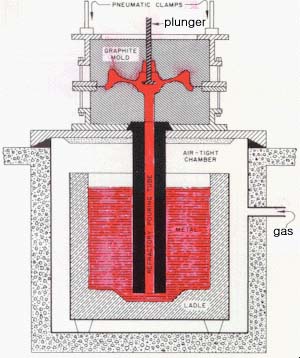

In contrast to the gravity pouring of conventional permanent-mold casting,

low-pressure permanent-mold casting forces the molten metal up through a vertical

tube by applying low pressure of 5 ~ 15psi to a molten bath below.

The figure provides an illustration of this process, which can be applied to

a wide variety of metals, including steel and cast iron.

|

|

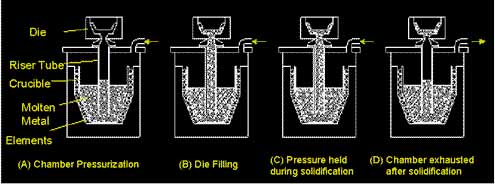

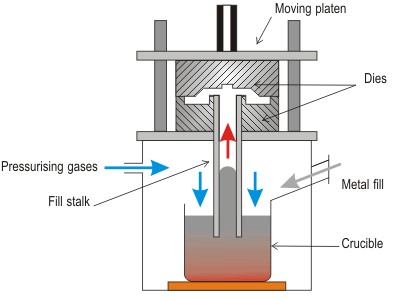

In low pressure die casting, molten metal is displaced vertically upwards into a die by means of low pressure on the liquid metal. The die cavity is filled slowly upwards which ensures no entrained air and high soundness. Castings, therefore, have better metallurgical integrity than die castings, and they can be heat-treated. The process, thus, has the benefits of die casting without the disadvantages. Tooling may be made in permanent or semi-permanent configurations. Tooling costs are about half those for pressure die casting. |

저압주조법 |

|