| 4 편 기 계 가 공 |

|---|

원주톱기계(circular sawing machine)

원주톱기계 |

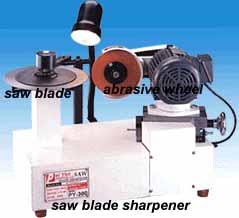

톱날연삭기

톱날연삭기

|

|

|

|

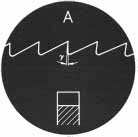

톱이의 형상 및 각도

Fine toothing / herringbone toothing |

This type of toothing having tooth pitches varying as per thickness and dimensions of blade between 0,8 and 6,3 mm has especially been developped for handling brittle short-chip materials. Owing to their tooth shape these herringbone teeth have a particularly small chip pocket. As a result of the relatively small tooth pitches this toothing is best suitable only for cutting minor depths or thin-walled stock. A general recommendation would be to use the smaller tooth pitches up to 2 mm inclusive for minor cutting depths up to 3 - 4 mm maximum whilst the larger pitches could be used up to about 15 mm cutting depth, or cross section, respectively, as a maximum. It is, of course, necessary to take into consideration also the materials to be handled as well as the cutting speed and the corresponding feed. If the chosen feeds are small it might be possible to work also with slightly larger cutting depths without tooth breaking. |

|

|

This type of toothing having tooth pitches varying as per thickness and dimensions of blade between 3,15 and 12,5 mm has a relatively large chip pocket of half-round shape rendering possible fine chip formation. Owing to these characteristics the field of use of this type of toothing is wider than that of the toothing as per DIN 1837. The coarse toothing in question is above all suited for handling larger cross sections and increased cutting depths. Varying as per the dimensions and the tooth pitch as well as the corresponding feed this type of toothing can be used for cutting depths and cross sections up to a maximum of 100 mm. This toothing can well be considered as the most universal type of toothing according to DIN. |

|

|

This so-called high-performance toothing is manufactured with the same pitches as the type of coarse toothing according to DIN 1838 B (but only from 1 mm saw blade thickness up). It is characterized by its chip-cutting tooth shape and, when handling stock of low up to medium mechanical strength it ensures high cutting capacity. The three-chip feature resulting from the precutter higher by about 0,15 - 0,3 mm - as per the tooth pitch concerned - than the finishing tooth results in a reciprocal load removal from the teeth. When re-sharpening the saw blades the difference in height between the precutting and the finishing teeth must carefully be taken into consideration. It should be noted here that this type of toothing can with preference be used - for the most part - for cutting jobs only because of the fact that, in the case of sawing or milling work not separating entirely the handled stock, an additional groove results in the bottom face of the cut produced by the higher precutter so that a level bottom face cannot be obtained. When taking into consideration the above explanations this type of toothing can for the rest be used over the whole range as it can coarse toothing as per DIN 1838 B. |

HSS Metal Cutting Circular Saw Blades

fine toothing according to DIN 1837 A

The table below shows the number of teeth for the different sizes.

| T h i c k n e s s i n m m |

Diameter in mm | |||||||||||||

| 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | ||

| 0,2 | 80 | 80 | 100 | 128 | 128 | |||||||||

| 0,25 | 64 | 80 | 100 | 100 | 128 | 160 | ||||||||

| 0,3 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | |||||||

| 0,4 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | |||||||

| 0,5 | 50 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | ||||||

| 0,6 | 50 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | |||||

| 0,8 | 50 | 50 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | |||||

| 1 | 40 | 50 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | 200 | |||

| 1,2 | 40 | 50 | 50 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | 200 | |||

| 1,6 | 40 | 40 | 50 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | 200 | ||

| 2 | 32 | 40 | 50 | 50 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | 200 | ||

| 2,5 | 32 | 40 | 40 | 50 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | 200 | |

| 3 | 32 | 32 | 40 | 50 | 50 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | 200 | |

| 4 | 24 | 32 | 40 | 40 | 50 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | |

| 5 | 24 | 32 | 32 | 40 | 50 | 50 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | |

| 6 | 24 | 24 | 32 | 40 | 40 | 50 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | |