|

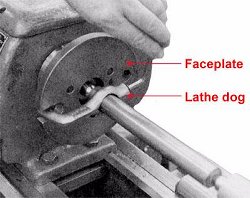

A lathe faceplate is the basic workholding accessory for a wood or metal turning lathe. It is a circular

metal (usually cast iron) plate which fixes to the end of the lathe spindle. The workpiece is then clamped to

the faceplate, typically using t-nuts in slots in the faceplate, or less commonly threaded holes in the

faceplate itself.

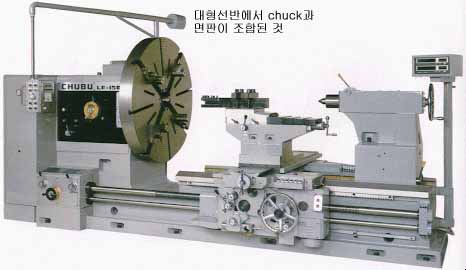

The faceplate may be attached to the lathe in several ways: The two most common are a thread and a precision

cone arrangement or threaded studs and a circular recess fitting a flange on the end of the spindle. Increasingly

common is the camlock arrangement where shaped studs and cams replace threaded studs for rapid exchanging of

the faceplate with other accessories, such as three or four jaw chucks.

The faceplate was the ancestor of lathe chucks, an arrangement of three or more adjustable 'dogs' bolted to the

faceplate providing a primitive chuck arrangement.

|