| 4 편 절 삭 가 공 |

|---|

|

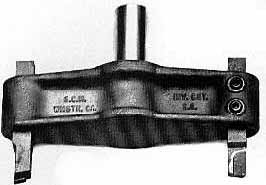

Trepanning 공구 |

||

|

Trepanning is a method of producing large deep holes economically from solid.

The process can also be used for boring tubing where heavy stock removal is needed.

A specially designed hollow tool cuts a narrow circular path in the workpiece

and leaves a solid core. Because all the material is not being removed,

the rate of penetration by trepanning is much faster than other methods.

The conventional method of producing a seamless tube by piercing and drawing is

limited to walls lighter than one-third of the outside diameter and and inside

diameter less then 12". The higher temperatures and pressures used in space

age and missile components have brought about an increased need for heavier

walled tubing, piping and pressure vessels.

Trepanning greatly increase the sizes available and does not limit the designer

to light walls and small I.D.s. |

||

fly cutter |

fly cutter |

saw cutter |

fly cutter |

|

|