|

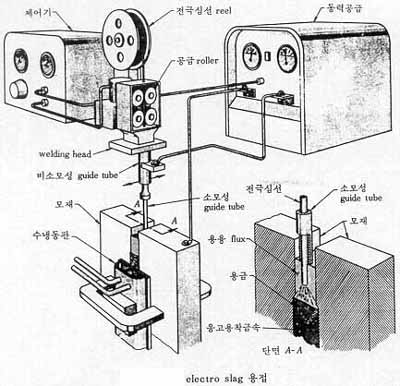

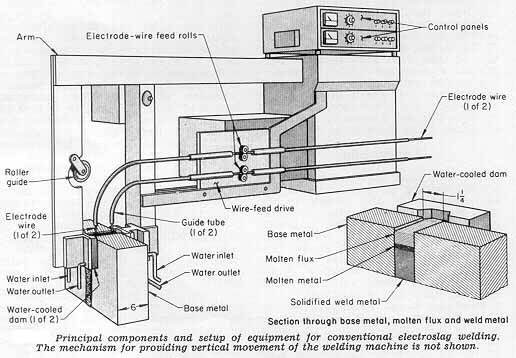

Narrow-gap Improved Electroslag Welding (NGI-ESW) using a consumable guide tube

Electroslag welding is a single-pass process. Once a weld begins, it continues without interruption.

The process requires a welding arc only at the beginning of the weld cycle. The arc heats a supply of

granular flux and forms a molten slag bath which extinguishes the arc.

Cross-Section of Weld in Progress

Cross-Section of Weld in Progress

The electrically-charged slag bath (hence the name electroslag) is resistant to the welding current passing through it.

This resistance heats the slag and keeps it molten at a temperature of approximately 3500° F (about 2000° Celcius).

The slag is hot enough at this temperature to sustain continuous melting of the welding wire without an arc.

The melted wire falls through the floating slag bath and joins the weld puddle.

The fluidity of the slag bath and molten weld puddle requires a containment method and forces a vertical weld.

(1) Consumable Guide Tube

Welding wire is pulled from its source, and fed down a steel tube to the molten puddle. The tube serves

to guide the wire between the two plates so that the neither the wire nor the tube touches the plates being joined.

This guide tube needs to be protected from touching the parent material to avoid a short that stops

the welding operation. To avoid this, the guide tube must be insulated. As the weld progresses and

the flux bath and weld puddle rise, the guide tube melts.

(2) Metal Transfer

Cross-Section of Weld, Enlarged View

Cross-Section of Weld, Enlarged View

It is important to understand how welding wire transfers into weld metal through the slag pool.

As wire passes through the flux bath to the molten weld pool, the melted wire transfers in droplet form,

down through the flux bath. Wire passes, in this manner, from a solid to a liquid to form weld metal.

During this process, the welding wire melts completely inside the slag pool before it reaches the surface

of the weld metal pool. As wire plunges into the molten flux bath, a certain amount of wire extends below

the end of the guide tube and into the top of the molten flux bath. This length of wire is

the "unsubmerged wire extension". Below this extension, an additional length of the wire plunges

into the molten slag bath. This length of wire is the "submerged wire extension".

This submerged portion of the wire is significant to the welding operation.

Heat generated in the wire extension occurs due to resistance of the metal wire.

The longer the length of wire submerged in the molten flux, the thinner the wire becomes.

The thinner the wire becomes, the greater resistance to current flow. The greater the resistance

to current flow, the greater the amount of heat generated by the current and the hotter the flux bath becomes.

Two things that increase submerged extensions are higher wire-feed speeds, and solid wire.

Solid wires have more mass than hollow-cored wires, and therefore take longer to transfer

from a solid to a liquid. This creates a longer submerged extension for solid wires,

and more resistant heating of the flux bath. The increased heating of the flux bath creates

a hotter and deeper weld metal pool. The depth of the weld metal pool directly affects

the grain formation "form factor" which determines the physical characteristics of an electroslag weld.

(3) Containment

Since an electroslag flux bath and resultant weld metal pool are so fluid, the process requires

a vertical position with devices to contain the fluids on the bottom and sides of the weld.

To ensure that complete fusion occurs at the start of each weld, a sump is attached to the bottom

of the material being welded. The depth of the sump allows the flux to melt and the molten weld pool

to liquify enough to tie in all sides of the parent material. The sump is usually cut into a "U" shape,

and tack welded to either side of the weld gap, on the bottom of the two plates being welded.

Since one inch of flux generally covers the molten weld puddle, run-off tabs are added to

the top of the plates being welded. When the flux puddle reaches the top, the weld metal

is still one inch below. Therefore, if two-inch run-off tabs are tack-welded to either side

of the weld gap, the flux puddle can rise two inches above the parent material. When the weld stops,

and the flux is cleaned off, weld metal should be one inch above the parent material.

Water-cooled copper shoes contain the molten weld puddle on either side of the gap between

the two pieces of parent material. The cavity formed between the two pieces of parent material

and the two copper shoes contains the molten slag bath and weld pool. The shape of the contoured face

of each copper shoe also determines the finished surface appearance of the weld bead.

Top View of Bad Copper Shoe Fit-Up

Top View of Bad Copper Shoe Fit-Up

As the weld is being produced, the slag bath comes in contact with the copper shoe

and cools which causes a thin layer of flux to deposit on the exposed portion of the shoe.

If the contact point of the copper shoe does not fit firmly against the parent material,

an air gap forms between the plate and the copper shoe. As the weld progresses,

hot flux flows between the shoe and the parent material, causing the plate to undercut.

(4) Maintaining flux levels

A certain amount of flux is lost as it plates against the copper shoes.

This lost flux is replaced periodically to maintain a depth of approximately one inch.

If the flux level falls lower than one inch, the weld becomes unstable.

The sound of the puddle is louder as the puddle becomes more agitated.

If the puddle depth shrinks too much (to less than one-half inch), arcing may occur

between the guide tube and the sidewalls of the parent material. To maintain a proper flux height,

flux is continually added to the puddle during the welding operation.

Sometimes the welding operator adds too much flux during the weld, and the puddle becomes too deep.

When the flux is too deep, it chills the weld and incomplete fusion, or cold-roll on the wet lines occurs.

Flux should be added only as needed. As operators gain more experience, the sound of the weld is

a guide for adding or withholding flux.

(5) Constant Voltage

Electroslag welding differs from the arc welding processes because there is no arc except at the beginning

of the weld. The resistance of the molten flux to the electrical current produces the heat needed for welding.

Conventional constant-voltage power sources allow easier control of the amperage and voltage.

Constant-current power sources are not recommended because control has proven difficult.

In constant-voltage systems, the power supply maintains the voltage at a constant level,

which gives a flat, or nearly flat, volt-ampere characteristic. Processes that require continuously

fed electrode wire frequently use this type of power source. Setting the voltage level

on the power source controls the welding voltage. The electrical load on the power supply controls the current.

The load varies by the speed of the welding wire feed and by the diameter of the wire.

That is why amperage varies so much during an electroslag weld.

As the slag puddle rises, it eventually reaches the bottom of the guide tube,

and submerses the guide tube in the molten puddle. The power supply sees this large cross-sectional load,

and increases current to supply the load. As the slag puddle melts the bottom of the guide tube,

a gap forms between the bottom of the guide tube and the top of the slag puddle

and power supply amperage decreases. In a like manner, as feed speed increases, power supply amperage increases.

As wire feed speed decreases, power supply amperage decreases. The self-regulating characteristic

of the constant-voltage power source comes about by the ability of this type of power source

to adjust its welding current in order to maintain a fixed voltage level.

# From Aircomatic

|