| 1 편 주 조 |

|---|

|

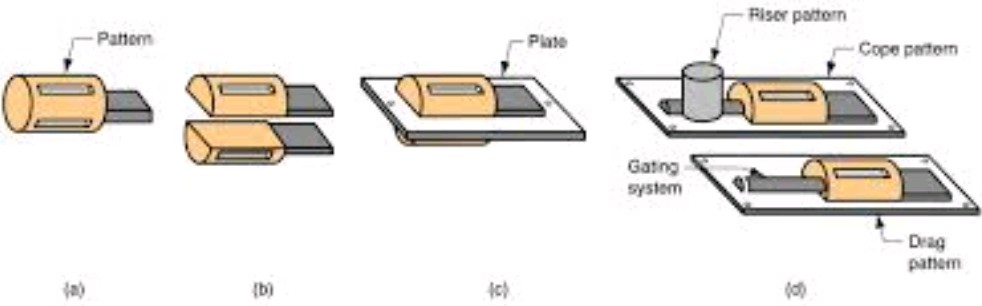

Match Plate Pattern

|

|

|

Large-quantity production of small castings requires match-plate patterns or more specialized types of pattern equipment. The cope and drag portions of the pattern are mounted on opposite sides of a wood or metal plate conforming to the parting line. Match plates are also integrally cast in which cast pattern and plate are cast as one piece in sand or plaster molds. It is used with some type of molding machine, in order to obtain maximum speed of molding. Advantages of the patterns are:

The match plate is the same as the mounted pattern with the exception that when you have part of the casting in the cope and part in the drag (split pattern), these parts are attached to the board or plate opposite each other and in the correct location so that when the plate is removed and the mold is closed the cavities in the cope and drag match up correctly. The molding procedure is the same as a one sided mounted plate.

|

|

|

|