|

Air Compressor and Chilling Unit

The free saturated air is sucked from atmosphere through a highly efficient dry-type suctionfilter into the

first stage of the horizontal balanced opposed, lubricated reciprocating air compressor. Compresssed air is

chilled to 12 degree centigrade in achilling unit ata temperature of 12 degree centigrade to a moisture separator

where the condensed moisture gets removed before entering into Molecular Sieve Battery. Before sending the air

to MOLECULAR SIEVE BATTERY, air is passed through an OIL ABSORBER where air becomes oil free.

Purification of Air

Chilled air passes through the Molecular Sieve Battery consisting of Twin Tower packed with Molecular Sieves

to remove moisture and Carbon dioxide present in the air.

Molecular Sieve Battery operates on Twin Tower System, when one tower is under production the other tower is

regenerated by passing waste Nitrogen gas at 200 degC through a reactivation heater. After interval of 8 to

10 hours, the tower under production gets exhausted and regenerated by similar process before use and thus

the cycle continues. Any dust particles gets filtered in the DUST FILTER before air enters

the air seperation column.

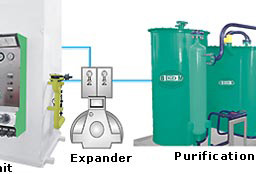

Air Separation

Chilled, Oilfree and moisture free air enters into multi-pass HEAT EXCHANGER NO.I where it gets cooled to

(-80) degC by cold gained from outgoing waste Nitrogen and Oxygen.

A part of air this enters a multi-pass HEAT EXCHANGER NO. II or LIQUIFIER made of special Alloy tubes. This

air cools to (-170) degC before passing through an expansion valve. Due to joule Thompson Effect, after

the expansion valve. Due to joule Thompson Effect, after the expansion valve, air gets further cooled down

and gets liquified before entering into bottom column is known as RICH LIQUID.

THE RICH LIQUID in the BOTTOM COLUMN enters into feed tray of top column enters into feed tray of top column.

Similarly the liquid nitrogen called POOR LIQUID enters into top column as a reflux & it takes away the latest

heat of condensing Oxygen and gets vapourised whereas the liquid Oxygen flows down the trays of the

top column into the condenser passes through a sub-cooler to a liquid oxygen pump.

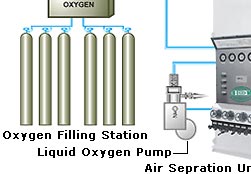

Cylinder Filling

Liquid oxygen pump pumps liquid oxygen through heat exchanger no. II and I, where liquidoOxygen gets gasified

before filling in cylinders in the filling manifold.

The pure bone dry oxygen gas at ambient temperature and high pressure is filled into oxygen cylinders through

manifold valves by means of the highly efficient reciprocating liquid oxygen pump.

|