|

Stretch Forming

|

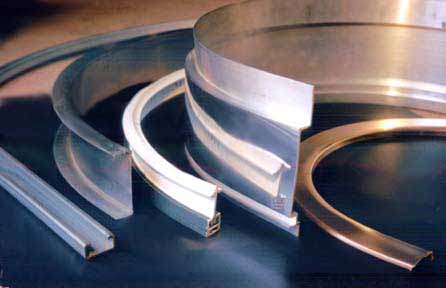

Stretch forming is a very accurate and precise method for forming metal shapes, economically.

The level of precision is so high that even intricate multi-components and snap-together

curtainwall components can be formed without loss of section properties or original design function.

Stretch forming capabilities include portions of circles, ellipses, parabolas and arched shapes.

These shapes can be formed with straight leg sections at one or both ends of the curve.

This eliminates several conventional fabrication steps and welding.

The variety of shapes and cross sections that can be stretch formed is almost unlimited.

Window systems, skylights, store fronts, signs, flashings, curtainwalls, walkway enclosures,

and hand railings can be accurately and precisely formed to the desired profiles.

Curvetech produces a superior finished product compared to other types of forming.

Close and consistent tolerances, no surface marring, no distortion or ripples,

and no surface misalignment of complex profiles are important benefits inherent in stretch forming.

A smooth and even surface results from the stretch forming process.

|

|

|

|

|

|