|

신선(伸線; wire drawing)

|

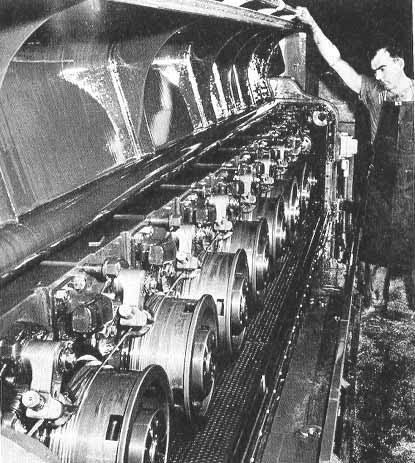

The wire rod to be drawn is pointed in the wire pointing machine. This pointed wire is inserted through

the die of the first wire drawing machine and fastened to a locking device on the drum. The drum is

then started. As the drum rotates, the wire fastened to the drum gets pulled and coiled around the

drum. Since the wire getting pulled is passed through the die having a higher inlet diameter and a

lower outlet diameter, the drawn wire diameter gets reduced.

The starting end of the drawn wire is released from the lock of the first drum, is passed through

the overhead loop and pulley provided, is brought down and is inserted through the die of the second

drum and drawn through this die for further reduction. Thus, the wire is drawn through all the wire

drawing drums of the set in a continuous manner to get the required finished diameter of the wire.

When the drum of the last wire drawing machine gets fully loaded with the drawn wire, the machine will

be stopped to unload the finished material and then restarted. (If one opts for the continuous

coiling machine, the drawing process will not have to be stopped for this purpose)

When the bundle of input rod finishes, the machine should be stopped. The end of this bundle is

welded to the end of a new bundle of rod using the butt welding machine. Then the process is to be

continued.

Also, in case of an accidental snapping of wire in between drums, the snapped ends are welded with the help of the butt welding machine and the process is continued.

|

연속신선기

연속신선기

|

연속신선기

연속신선기

|

|