|

전기적 특수가공(electrical machining)

|

-

(1) 전해연마(electrolytic polishing, Electopolishing):

Electrolytic polishing(Electopolishing) is an anodic dissolution of material from the specimen surface in

an electrolytic cell. After a short pre-treatment, the specimen is immersed in an electrolytic solution

(electrolyte), a direct, electrical current is applied so that the specimen becomes the anode and a

nearby metal conductor becomes the cathode, and material is removed from the surface in the

electrolytic reaction. This electrochemical treatment of metals helps to obtain a smooth and corrosion-resistant

finish of them.

Electrolytic Polishing or electropolishing, is widely used in the metallography of stainless steels, copper alloys,

aluminum alloys, magnesium, zirconium and other metals that are difficult to polish by conventional mechanical methods.

Electropolishing can completely remove all traces of worked metal remaining from mechanical grinding and polishing

operations used in specimen preparation. When electro polishing is used in metallography, it is preceded by mechanical

grinding (and sometimes polishing), and followed by etching.

|

|

|

-

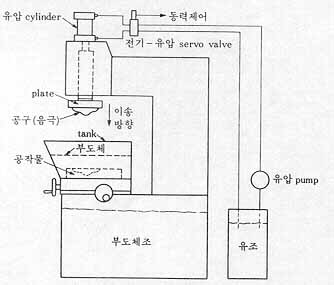

(2) 전해가공(electrochemical machining, ECM):

ECM is a method of removing metal by an electrochemical process. It is used for working extremely hard materials or

materials that are difficult to machine using conventional methods. Its use is limited to electrically conductive

materials; however, this includes all metals. ECM can cut small or odd-shaped angles, intricate contours or cavities

in extremely hard steel and exotic metals such as titanium, hastelloy, kovar, inconel and carbide.

ECM is similar in concept to Electrical discharge machining in that a high current is passed between an electrode and

the part, through an electrolyte material removal process having a negatively charged electrode (cathode), a conductive

fluid (electolyte), and a conductive workpeice (anode); however, in ECM there is no tool wear. The ECM cutting tool is

guided along the desired path very close to the work but it does not touch the piece. Unlike EDM however, no sparks are

created. The workpiece is eroded away in the reverse process to electroplating. Very high metal removal rates are possible

with ECM, along with no thermal or mechanical stresses being transferred to the part, and mirror surface finishes are

possible.

As far back as 1929, an experimental ECM process was developed by W.Gussef, although it took until 1959 for a commercial

process to be established by the Anocut Engineering Company. Much research was done in the 1960s and 1970s, particularly

in the gas turbine industry. The rise of EDM in the same period largely stopped research into ECM in the west, although

work continued behind the Iron Curtain. The original problems of poor dimensional accuracy, and environmentally polluting

waste have largely been overcome, although the process remains a niche technique. The cutting heads on all Philips '

Philishave' shavers are made using ECM.

The ECM process is most widely used to produce complicated shapes with good surface finish in difficult to machine

materials, such as turbine blades. It is also widely and effectively used as a deburring process.

In the deburring process, the ECM uses techniques as described above to remove pieces of metal that are left over from

the machining process, and to dull out sharp edges. This process is very fast and much more convenient than the

conventional method of deburring by hand. It will tend to leave better surface finishing, and no metal deformation

will occur because the tool piece doesn’t actually touch the metal.

|

-

(3) 방전가공(electrodischarge machining, EDM):

Electrical Discharge Machining (or EDM) is a machining method primarily used for hard metals or those that would be

impossible to machine with traditional techniques. One critical limitation, however, is that EDM only works with

materials that are electrically conductive, and generaly those materials are ferrous alloys. EDM can cut small or

odd-shaped angles, intricate contours or cavities in pre-hardened steel without the need for heat treatment to soften

and re-harden them as well as exotic metals such as titanium, hastelloy, kovar, and inconel.

Sometimes referred to as spark machining or spark eroding, EDM is a non-traditional method of removing material by a

series of rapidly recurring electric arcing discharges between an electrode (the cutting tool) and the workpiece, in

the presence of an energetic electric field. The EDM cutting tool is guided along the desired path very close to

the work but it does not touch the piece. Consecutive sparks produce a series of micro-craters on the work piece and

remove material along the cutting path by melting and vaporization. The particles are washed away by the continuously

flushing dielectric fluid. It is also important to note that a similar micro-crater is formed on the surface of the

electrode, the debris from which must also be flushed away. These micro-craters result in the gradual erosion of

the electrode, many times necessitating several different electrodes of varying tolerances to be used, or, in the

case of wire EDM machining, constant replacement of the wire by feeding from a spool.

There are two main types of EDM machines: Sinker EDM (also called Conventional EDM and Ram EDM) and Wire EDM.

Advantages

- complex shapes that would otherwise be difficult to produce with conventional cutting tools

- extremely hard material to very close tolerances

- very small work pieces where conventional cutting tools may damage the part from excess cutting tool pressure.

Disadvantages

- Some of the disadvantages of EDM include:

- the inability to machine non-conductive materials.

- the slow rate of material removal.

- the additional time and cost used for creating electrodes for ram / Sinker EDM.

- reproducing sharp corners on the workpiece is difficult due to electrode wear.

|