|

A water jet cutter is a tool capable of slicing into metal or other materials using a jet of water at high velocity and

pressure, or a mixture of water and an abrasive substance. The process is essentially the same as water erosion found

in nature but accelerated and concentrated by orders of magnitude. It is often used during fabrication or manufacture of

parts for machinery and other devices. It has found applications in a diverse number of industries from mining to

aerospace where it is used for operations such as cutting, shaping, carving, and reaming.

Operation

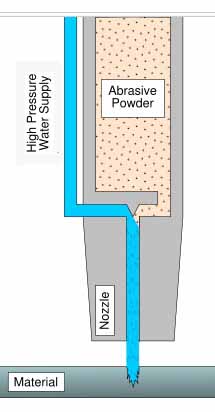

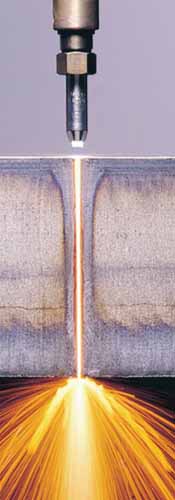

A water jet cutter creating a specialist toolThe cutter is commonly connected to a high-pressure water pump

(a local water main does not supply sufficient pressure) where the water is then ejected from the nozzle, cutting

through the material by spraying it with the jet of high-speed water. Additives in the form of suspended grit or

other abrasives, such as garnet and aluminum oxide, can assist in this process. Because the nature of the cutting

stream can be easily modified, water jets can be used to cut materials as diverse as fish sticks, 'gas station'

sandwiches, and titanium. There are few materials that cannot be effectively cut with a water jet cutter; one of

these is tempered glass, which shatters when cut, regardless of the cutting technology used. Certain ceramics are

also resistant to water jet cutting. Water jet cuts are not typically limited by the thickness of the material, and

are capable of cutting materials over twelve inches (30 cm) thick. The penetrating power of these tools has led to the

exploration of their use as anti-tank weapons, however, due to their short range and the advent of composite armor,

research was discontinued.

Benefits

An important benefit of the water jet cutter is the ability to cut material without interfering with the material's

inherent structure as there is no "heat affected zone" or HAZ. Minimizing the effects of heat allows metals to be cut

without harming or changing intrinsic properties.

Water jet cutters are also capable of producing rather intricate cuts in material. The kerf, or width, of the cut can

be changed by changing parts in the nozzle, as well as the type and size of abrasive. Typical abrasive cuts are made

with a kerf in the range of 0.04" to 0.05" (1.016 to 1.27 mm), but can be as narrow as 0.02" (0.508 mm). Non-abrasive

cuts are normally 0.007" to 0.013" (0.178 to 0.33 mm), but can be as small as 0.003" (0.0076 mm), which is approximately

the size of a human hair. These small cutters can make very small detail possible in a wide range of applications.

|