|

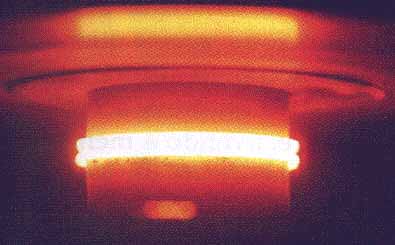

Friction welding(FW) is a class of solid-state welding processes that generates heat through mechanical

friction between a moving workpiece and a stationary component, with the addition of a lateral force called

"upset" to plastically displace and fuse the materials. Technically, because no melt occurs, friction

welding is not actually a welding process in the traditional sense, but a forging technique. However,

due to the similarities between these techniques and traditional welding, the term has become common.

Friction welding is used with metals and thermoplastics in a wide variety of aviation and automotive

applications.

Benefits

The combination of fast joining times of the order of a few seconds, and the direct heat input at the

weld interface, gives rise to relatively small heat affected zones. Friction welding techniques are

generally melt-free, which offers the advantage of avoiding grain growth in engineered materials such

as high-strength heat-treated steels. Another advantage is that the motion tends to "clean" the surface

between the materials being welded, which means they can be joined without as much prior preparation.

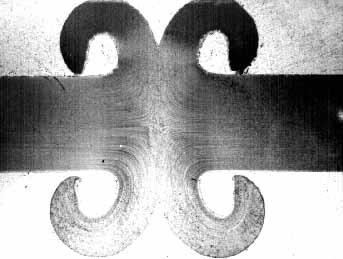

During the welding process, depending on the method being used, small pieces of the "plastic" metal will

be forced out of the working mass in rippled sheets of metal known as "flash". It is believed that the

flash carries away debris and dirt.

Another advantage of friction welding is that it allows dissimilar materials to be joined.This is

particularly useful in the aerospace field, where it is used to join lightweight aluminum stock to

high-strength steels. Normally the wide difference in melting points of the two materials would make

it impossible to weld using traditional techniques, and would require some sort of mechanical connection

instead (bolts, etc.). Friction welding provides a "full strength" bond with no additional weight.

Another common use for these sorts of bi-metal joins is in the nuclear industry, where copper-steel

joints are common in the reactor cooling systems.

Friction welding is also used with thermoplastics, which act in a fashion analogous to metals under

heat and pressure. The heats and pressures used on these materials are much lower than on metals, but

the technique can be used to join metals to plastics with the metal interface being machined.

For instance, the technique can be used to join eyeglass frames to the pins in their hinges. The lower

energies and pressures used allows for a wider variety of techniques to be used.

|

마찰용접부

마찰용접부

마찰용접부

마찰용접부