|

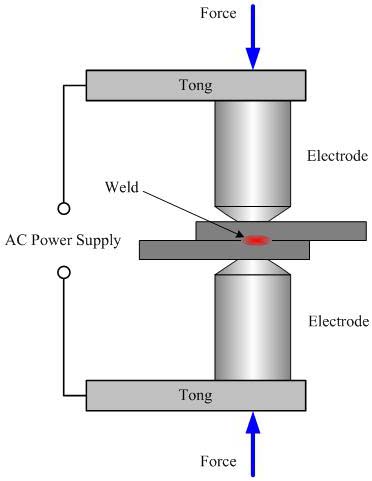

Spot welding is a type of resistance welding used to weld various sheet metal products. Typically the sheets are

in the 0.5-3.0 mm thickness range. The process uses two shaped copper alloy electrodes to concentrate welding

current into a small "spot" and to simultaneously clamp the sheets together. Forcing a large current through

the spot will melt the metal and form the weld. The attractive feature of spot welding is a lot of energy

can be delivered to the spot in a very short time (ten to one hundred milliseconds).

That permits the welding to occur without excessive heating to the rest of the sheet.

The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and

the amplitude and duration of the current. The amount of energy is chosen to match the sheet's material

properties, its thickness, and type of electrodes. Applying too little energy won't melt the metal or will

make a poor weld. Applying too much energy will melt too much metal and make a hole rather than a weld.

Another attractive feature of spot welding is the energy delivered to the spot can be controlled to produce

reliable welds.

Applications

Spot welding is typically used when welding particular types of sheet metal. Thicker stock is more difficult

to spot weld because the heat flows into the surrounding metal more easily. Spot welding can be easily identified

on many sheet metal goods, such as metal buckets. Aluminum alloys can also be spot welded. However, their much

higher thermal conductivity and electrical conductivity mean that up to three times higher welding currents

are needed. This requires larger, more powerful, and more expensive welding transformers.

|