|

The Process

Continuous casting is the process whereby molten metal is solidified into a "semifinished" billet, bloom, slab

or beam blank. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary

moulds to form "ingots". Since then, "continuous casting" has evolved to achieve improved yield, quality,

productivity and cost efficiency. Nowadays, continuous casting is the predominant way by which steel is produced

in the world. Continuous casting is used to solidify most of the 750 million tons of steel, 20 million tons of

aluminum, and many tons of other alloys produced in the world every year.

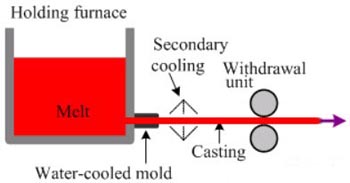

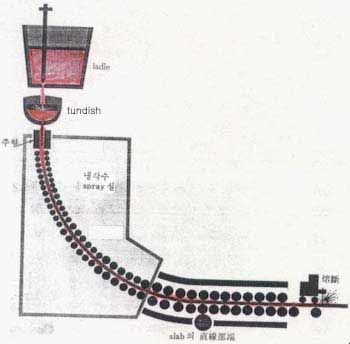

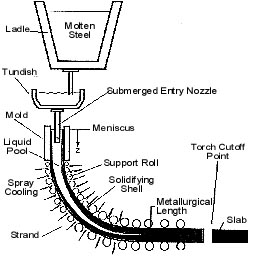

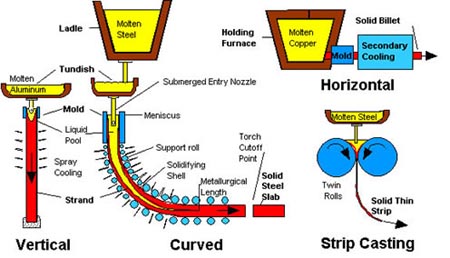

In the continuous casting process, illustrated in Figure 1, molten metal is poured from the ladle into the tundish a

nd then through a submerged entry nozzle into a mould cavity. The mould is water-cooled so that enough heat is

extracted to solidify a shell of sufficient thickness. The shell is withdrawn from the bottom of the mould at a

"casting speed" that matches the inflow of metal, so that the process ideally operates at steady state. Below

the mould, water is sprayed to further extract heat from the strand surface, and the strand eventually becomes

fully solid when it reaches the ''metallurgical length''.

Solidification begins in the mould, and continues through the different zones of cooling while the strand is

continuously withdrawn at the casting speed. Finally, the solidified strand is straightened, cut, and then

discharged for intermediate storage or hot charged for finished rolling.

To start a cast, the bottom of the mould is sealed by a steel dummy bar. This bar prevents liquid metal from

flowing out of the mould and the solidifying shell until a fully solidified strand section is obtained.

The liquid poured into the mould is partially' solidified in the mould, producing a strand with a solid outer

shell and a liquid core. In this primary cooling area, once the steel shell has a sufficient thickness,

the partially solidified strand will be withdrawn out of the mould along with the dummy bar at the casting speed.

Liquid metal continues to pour into the mould to replenish the withdrawn metal at an equal rate. Upon exiting

the mould, the strand enters a roller containment section and secondary cooling chamber in which the solidifying

strand is sprayed with water, or a combination of water and air (referred to as "air-mist") to promote

solidification. Once the strand is fully solidified and has passed through the straightener, the dummy bar is

disconnected, removed and stored.

Tundish

The shape of the tundish is typically rectangular. Nozzles are located along its bottom to distribute liquid steel

to the mould. The tundish also serves several other key functions:

- Enhances oxide inclusion separation.

- Provides a continuous flow of liquid steel to the mould during ladle exchanges.

- Maintains a steady metal height above the nozzles to the mould, thereby keeping steel flow uniform.

- Provides more stable stream patterns to the mould.

Mould

The main function of the mould is to establish a solid shell sufficient in strength to support its liquid core

upon entry into the secondary spray cooling zone.

The mould is basically an open-ended box structure, containing a water-cooled inner lining fabricated from a high

purity copper alloy. The inner face of the copper mould is often plated with chromium or nickel to provide a harder

working surface, and to avoid copper pickup on the surface of the cast strand, which can otherwise facilitate

surface cracks on the product.

Mould oscillation is necessary to minimize friction and sticking of the solidifying shell, and avoid shell tearing, and liquid steel breakouts, which can wreak havoc on equipment and machine downtime due to clean up and repairs. Friction between the shell and mould is reduced through the use of mould lubricants such as oils or powdered fluxes. Oscillation is achieved either hydraulically or via motor-driven cams or levers which support and reciprocate (or oscillate) the mould.

Product Types

Depending on the design of the casting machine, the as-cast products of the continuous cast process are slabs,

blooms, billets, or beam blanks.

Heat Transfer in Continuous Casting

By its nature, continuous casting is primarily a heat-extraction process. The conversion molten metal into a

solid semi-finished shape involves the removal of the following forms of heat:

- superheat from the liquid entering the mould from the tundish.

- the latent heat of fusion at the solidification front as liquid is transformed solid, and finally

- the sensible heat (cooling below the solidus temperature) from the solid shell

These heats are extracted by a combination of the following heat-transfer mechanisms:

- convection in the liquid pool.

- heat conduction down temperature gradients in the solid shell from the solidification

front to the colder outside surface of the cast, and

- external heat transfer by radiation, conduction and convection to surroundings.

Also not less important is heat transfer before the molten metal is poured into the mould. or instance,

in the casting of steel, heat transfer is important before the steel enters the mould because control of

superheat in the molten steel is vital to the attainment of a predominantly equiaxed structure and good

internal quality. Thus, conduction of heat into ladle and tundish linings, the preheat of these vessels,

convection of the molten steel and heat losses to the surroundings also play an important role in continuous casting.

Because heat transfer is the major phenomenon occurring in continuous casting, it is also the limiting factor

in the operation of a casting machine. The distance from the meniscus to the cut-off stand should be greater

than the metallurgical length, which is dependent on the rate of heat conduction through the solid shell and

of heat extraction from the outside surface, in order to avoid cutting into a liquid core. Thus, the casting

speed must be limited to allow sufficient time for the heat of solidification to be extracted from the strand.

Heat transfer not only limits maximum productivity but also profoundly influences cast quality, particularly

with respect to the formation of surface and internal cracks. In part, this is because metals expand and contract

during periods of heating or cooling. That is, sudden changes in he temperature gradient through the solid shell,

resulting from abrupt changes in surface heat extraction, causes differential thermal expansion and the generation

of tensile strains. Depending on the magnitude of the strain relative to the strain-to-fracture of the metal

and the proximity' of the strain to the solidification front, cracks may form in the solid shell. The rate

of heat extraction also influences the ability of the shell to withstand the bulging force due to the ferrostatic

pressure owing to the effect of temperature on the mechanical properties of the metal. Therefore, heat transfer

analysis of the continuous casting process should not be overlooked in the design and operation of a continuous

casting machine.

|