|

목 차

1 장 개 요(교과서 p.612)

기술의 발전에 따라 고정도, 고능률의 가공이 요구되고 있으며, 새로운 기계재료의 출현으로

상용가공법(常用加工法)으로 가공이 어려운 경우가 많다. 지금까지 기술한 상용가공법 외의

방법으로 가공하는 것을 특수가공이라 하여 본편에서 다루기로 한다. 본편에서는 특수가공을

기계적 특수가공, 화학적 특수가공, 전기적 특수가공으로 나누어 기술하나, 문헌에 따라서는

절삭공구나 연삭숫돌과 같이 실체(實體)의 공구를 사용하는 가공법을

상용가공법(常用加工法; conventional machining processes), 전기, 전자, 열 등과 같이 실체가 없는 공구에

의한 가공법을 특수가공법(unconventional processes, non-traditional processes)으로 분류하므로,

분류기준에 의미를 두지 말고 각 가공법과 적용범위 및 특징에 관심을 갖기 바란다.

[1] 기계적 특수가공

(1) grit blasting:

주물의 표면을 청정(淸淨)하거나, 도금 및 도장 전에 고압의 공기로 석영사(石英砂; sand)를 분사시켜

불순물을 제거하고 다듬질하는 방법을 sand blasting이라 하고, 모래 대신에 작은 강구(鋼球; shot)를

사용하는 가공을 shot peening, 강구를 파쇄한 grit를 사용하는 가공을 grit blasting이라 한다.

-

sand blasting에 의하여 금속표면의 녹을 제거한다.

sand blasting에 의하여 금속표면의 녹을 제거한다.

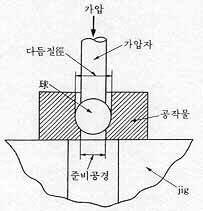

(2) burnishing:

원통의 내면을 다듬질할 때 그림과 같이 원통의 안지름보다 약간 큰 강구(鋼球)나 초경합금구(超硬合金球)를

압입(壓入)함으로써 내면의 거친 요철을 압궤(壓潰)하여 다듬질면을 얻는 방법을 burnishing, ball burnishing

또는 ball finishing이라 하고,

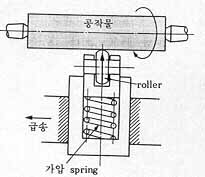

선반 등으로 가공된 표면의 뜯긴 자국 및 절삭공구의 형상에 의한 요철을 그림과 같이 roller로 압궤하는

것을 roller burnishing 또는 roller finishing 이라 한다.

|

ball burnishing

ball burnishing

|

roller burnishing

roller burnishing

|

[2] 화학적 특수가공

대부분의 재료는 화학적으로 용해(溶解) 및 부식(腐蝕)시킬 수 있으며, 이런 현상을 이용한 가공법을

화학적 가공법(chemical machining, chemical milling)이라 한다. 복잡한 형상, 가공면이 넓고 기계적 부하를

피해야 하는 경우 및 기계적인 지지가 어려운 공작물 등의 가공에 이용된다.

오래 전부터 녹을 제거하는 산세정(酸洗淨), 공예에서의 etching 및 금속표면의 광휘침지(光輝浸漬) 등에

화학적 특수가공법이 적용되었으나 최근에는 단순하게 표면처리에 국한하지 않고 재료의 제거를 목적으로 하는

가공법의 일종으로서 지위를 갖게 되었다.

[3] 전기적 특수가공

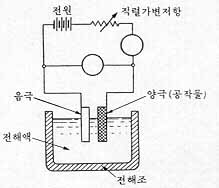

(1) 전해연마(electrolytic polishing):

전해연마(electrolytic polishing)는 전기도금과는 반대로 공작물을 양극(陽極)으로 하여 적당한

용액 중에 넣어 통전하면 양극의 용출작용(溶出作用)에 의하여 닦음질되고 광택이 난다.

전해연마

전해연마

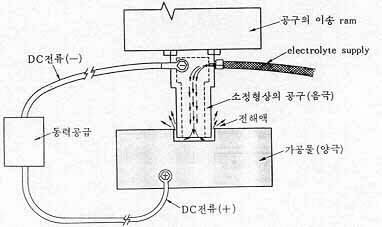

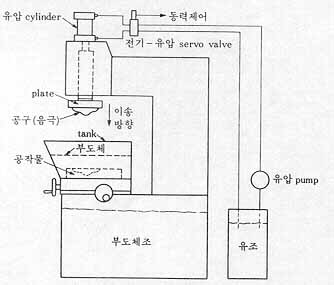

(2) 전해가공(electrochemical machining):

전해가공(electrochemical machining)은 전해연마의 전기화학적 반응을 보다 크게 하고 기계적 작용을

첨가시켜 내열강, 초경합금, 고장력강 등과 같이 상용가공하기 어려운 것을 가공하는 방법으로서,

그림과 같이 공작물을 양극으로 하고 음극전극과 함께 alkali 성의 전해액에 넣어 가공부를 전해시켜서

구멍을 뚫거나 홈파기를 한다.

전해가공

전해가공

(3) 방전가공(electrodischarge machining):

전극과 가공물을 등유 등과 같은 가공액 중에서 0.04mm 정도의 간격을 유지한 상태에서 양자 사이에

100V 정도의 전압을 가하면 절연(絶緣)이 깨져 방전(放電)이 생긴다.

이 불꽃방전(spark discharge)에 의하여 재료를 미량(微量)씩 용해(熔解)하여 제거하는 방법을 이용한 가공을

방전가공(electrodischarge machining, EDM)이라 하며 구멍뚫기, 조각, 절단 등에 이용된다.

방전가공

방전가공

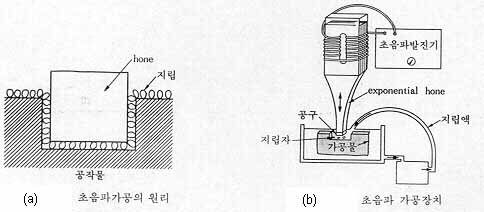

(4) 초음파가공(ultrasonic machining):

그림과 같이 초음파진동을 하는 공구와 공작물 사이에 지립(砥粒)과 공작액을 넣고 공구에 초음파진동을 주면 지립이

공작물에 충돌하여 전사가공(轉寫加工)을 하는 것을 초음파가공(ultrasonic machining)이라 한다.

유리, ceramics, 반도체 등 비금속재료와 stainless 강과 같은 금속재료에 die 조각, 이형관통(異形貫通)구멍,

pipe 형상의 공구에 의한 blanking 등에 이용된다.

초음파가공

초음파가공

|

관련 sites

- Shot Peening

Shot Peening Shot Peening

- Electrochemical machining

- Chemical Machining

- Electrical discharge machining

Grit Blasting Grit Blasting

Sand Blasting Sand Blasting

Sand/Shot/Grit Blasting Sand/Shot/Grit Blasting

- Burnishing

Roller burnishing Roller burnishing

Electro Polishing Electro Polishing

Electrochemical Machining Electrochemical Machining

Electrical Discharge Machining Electrical Discharge Machining

-

-

|